- Organic materials can be relatively cheap, however, transport and spreading costs can be much higher than for conventional fertilisers.

- Biosolids can be used as a substitute for fertiliser but only with an EPA approved management plan.

- All biochars or composts are not the same.

- Dairy effluent should be spread over a minimum of 1 ha/20 cows milked.

Key points

Background

Organic materials, such as animal manures, crop residues, composts and sewage sludge (biosolids), have been used in agriculture to supply plant nutrients and improve soil properties since cultivation of crops began. There is now a wider list of organic amendments that are applied in agricultural situations including biosolids, poppy mulch & seed waste, composts, bedding straw, vegetable & fish processing waste, dairy effluent (green water & sludge), dairy factory whey waste, chicken & pig manure, coal dusts and biochar, bacteria mixes, humates, compost teas and biodynamic preparations. The term ‘organic’ refers to the origin of products from animal or plant tissues, not to certification for use in organic production. When considering a new alternative product for your soil you should consider these key questions.

- What soil constraints, both chemical and physical, occur in your paddock? Have you done a recent soil test and what inherent issues occur with this soil type?

- Have you information on the ingredients of the product and what are the individual nutrient and organic matter contents?

- How likely is the selected product to address the identifies issues?

- Has there been any local independent testing of the products and results produced? In other words, where is the evidence for benefits?

Organic amendments are often applied to soil in lieu of inorganic fertiliser to supply essential plant nutrients. Large quantities of organic materials are typically required to supply the equivalent amount of nutrient applied as conventional fertiliser. Organic materials may be processed and combined into customised solid (granulated, pelletised) or liquid products that are convenient to use. Processed organic amendments may be enriched with mineral synthetic nutrients to provide all or most major and minor elements to crops. Organic products (e.g. chicken manure or seaweed-based fertilisers) may not be labelled with nutrient content information unless they have been manufactured into pellets or granules and have standardised nutrient contents. When planning to use a batch of organic fertiliser, it is important to ask for a nutrient analysis and a batch analysis that includes a contaminant analysis, sampled and analysed according to the Australian Standard for Composts, soil conditioners and mulches (AS 4454—2012) prior to purchase (Soil Wealth & Integrated Crop Protection 2022).

The majority of nutrients are not immediately available from organic materials as in conventional fertilisers but tend to be released slowly as the material decomposes with potentially unknown or variable degradation or release rates due to variations in temperature and moisture. Most nutrients in conventional fertilisers are available soon after application but the release of nutrients from organic matter through metabolism by microbes, can take from days to months to occur. Nitrogen is the main nutrient considered with additions of organic amendments but most manure also contains P, which can build up in the soil to excessive amounts with continuous manure applications. Some organic products can have a high salt content, which can “burn” plants if the material is applied in large quantities (Hardie and Cotching 2009). Trace elements may also be present in greater quantities than in conventional fertilisers (Cotching and Coad 2011). Reuse of organic materials is desirable in order to reduce waste streams and to take advantage of the soil benefits associated with added organic matter and plant nutrients. Organic materials can be relatively cheap, however, transport and spreading costs can be much higher than for conventional fertilisers and should be considered when calculating economic value (Havilah et al. 2005).

Poppy (Papaver somniferum) mulch, poppy seed waste, poultry litter, anaerobically digested biosolids (ADB), Lime-amended biosolids (LAB), compost and pyrethrum waste are all products rich in organic matter that are produced in sufficient quantity for application to agricultural land in Tasmania. The nutrient quality of these products is highly variable due to differences in inputs, processing, waste treatment and moisture content. An analysis of the material is recommended before application to mitigate any risks and guide its long-term use. Despite having beneficial properties, biosolids may pose human health and environmental risks if not carefully managed. Consequently, re-use of biosolids is a regulated activity in Tasmania (EPA 2020).

Pyrethrum marc, a waste product of pyrethrin extraction from dried flowers of the pyrethrum plant, can offer benefits as a soil conditioner and as a source of nutrients for crops. One or multiple applications of pyrethrum marc at 25 – 100 T/ha resulted in increased yields of onion and broccoli crops but not peas or carrots (Horticulture Innovation Australia Limited 2016). The benefits may be due to the nitrogen supplied by the pyrethrum marc. Pyrethrum marc supplied at $60-65 /T delivered, would provide at least similar economic returns to using conventional fertiliser. Using different application rates and/or frequency/timing, or a combination of marc plus fertiliser may provide even better returns.

Composts

A composted product has undergone a controlled aerobic and higher temperature biological transformation for a period of not less than 6 weeks that results in a stable and mature product without a cellular structure that is characteristic of plants or animals (RMCG 2020). Compost can be considered a ‘soil improver’ rather than a fertiliser replacement and the nutrient content can be highly variable (ISWA 2020). Nutrient content is only high if manures or biosolids are included as feedstocks. Often composted products are supplemented with particular nutrients to achieve a desired nutrient range and balance. Depending on the origin, treatment and intended use of soil amendments from recycled organics, regulations or codes of practice apply to their use.

Compost is usually broadcast over the entire paddock prior to crop planting and worked into the soil. Research has shown the positive effect of compost on soil organic matter content and other soil health attributes such as increased soil aggregate stability, soil porosity, and water holding capacity, increased cation exchange capacity, reduced compaction, increased soil microbial biomass and activity, as well as suppression of plant pathogens (RMCG 2020). Composts in Australia are relatively low in nutrients unless produced with the addition of manure or biosolids or augmented with mineral fertilisers. While composts are not high in nutrients, they may improve soil conditions, microbial activity and access to nutrients.

Biosolids

Biosolids are a by-product of municipal sewage and wastewater treatment. During sewage treatment, microorganisms digest the sewage, breaking down the organic solids leaving wastewater and biosolids. The water content of the solids is then reduced. Lime amended biosolids are produced by blending sludge with lime. Water in the sludge reacts with the lime, producing heat, and together with the high pH (12) this kills pathogens and is known as stabilising the sludge that can then be safely applied to land. Biosolids contain macronutrients (nitrogen, phosphorus, potassium and sulphur), micronutrients (copper, zinc, calcium, magnesium, iron, boron, molybdenum and manganese), and may also contain lime if this is added during treatment, and may also contain traces of metal compounds, including arsenic (As), cadmium (Cd), chromium (Cr), lead (Pb), mercury (Hg), nickel (Ni) and selenium (Se) (Tasmanian Institute of Agricultural Research 2008).

The source (urban or industrial) can mean that biosolids contain variable contents of micro-nutrients. Small beneficial amounts of boron, copper, molybdenum, selenium and zinc can be present in biosolids. However, trace amounts of the toxic metals arsenic, cadmium, chromium, lead, manganese, nickel and mercury may also be present depending on their source. The concentration of metal contaminants in the soil determines the rate of application. The amount of metals removed by most agricultural crops is very small and care needs to be taken to prevent inappropriate application of biosolids containing elevated levels of metals (Tasmanian Institute of Agricultural Research 2008b). However, the application of biosolids at rates that are practical to manage was not found to result in the uptake of Cd or Pb that exceeded the maximum permitted limit for heavy metals in foods (Cotching and Coad 2011).

Biosolids may have a musty or ammonia-type odour normally caused by sulphur and ammonia compounds (both plant nutrients). The extent of odour will be dependent on temperature, wind speed and wind direction. Odour can be present in the immediate vicinity of the application site, however this odour is short lived. Odour usually dissipates within a day of spreading and incorporating biosolids into topsoil also helps to reduce odours. Biosolids stabilisation with lime reduces or eliminates pathogens. While all biosolids will contain some level of pathogens, the open-air agricultural environment is very effective at reducing pathogen numbers as surface spreading in fine weather allows sunlight to kill the pathogens, or direct injection into the soil provides a physical barrier over the biosolids. Pathogens decline to undetectable levels by 12 months after application. Biosolids products must be transported and applied to land in ways that avoid public nuisance, particularly with respect to odour. Transport routes and site access must be chosen to minimise public nuisance, in both rural and urban areas. In Tasmania biosolids must be transported by appropriately approved or registered waste transport businesses. The application rate of biosolids to land must not exceed permitted soil contaminant concentrations, the predicted nitrogen requirements of the crop to be grown on the site, or the lime requirements of the soil. Refer to the Guidelines for details EPA (2020). While the current guidelines do not limit application based on phosphorus rates, it recommended to check soil P levels including PERI or M3PSR and P levels in the biosolids to ensure the environmental risk of P run-off or leaching is controlled. Prior to applying biosolids, all paddocks must undergo soil analysis for background levels of nutrients, pH and heavy metals. Biosolids used on agricultural land must also be analysed for nutrients and a range of contaminants. The Guidelines impose limits for heavy metals and organic contaminants, in both soil and biosolids, which must be adhered to before land application of biosolids can commence. The Guidelines stipulate delay periods for harvesting of different food crops (30 days to 18 months) plus withholding periods for animal grazing (e.g. 30 days).

The available nitrogen content of biosolids is dependent on the treatment processes used. Research in Tasmania suggests that an application rate of 23 wet t/ha of biosolids supplies about 50 kg/ha of available nitrogen in the first year after application, which is sufficient for growing cereal crops (Ives et al. 2011). Nitrogen available in subsequent years is likely to be of the order of 10 and 2 kg/ha in the second and third years after application. Autumn applications of biosolids to fallow cropping land should be avoided, as nitrogen losses can be high due to leaching during winter. Biosolids can supply the phosphorus requirements for grass and cereal crops. Crops such as potatoes will require additional fertiliser depending on the phosphorus status of the soil. All biosolids are low in potassium and farmers should apply the standard recommended rates using mineral fertilisers. Beneficial amounts of sulfur are available for crop growth with an application rate of 23 wet t/ha of biosolids supplying an equivalent of 10 kg/ha of available sulfur in the year after application. Lime amended biosolids can be used as an alternative to agricultural lime. The application of 23 wet t/ha of lime amended biosolids to the surface of a sandy loam soil resulted in an increase in soil pH of 0.5 units and when the biosolids were mixed into the upper 10cm of soil, the pH increased by 0.9 units. Changes in pH are likely to be less on clay textured soils but greater on sands (Tasmanian Institute of Agricultural Research 2008b).

Biosolids are slightly cheaper per hectare than inorganic fertilisers in the first year after application but once the residual value of N and P are considered, biosolids becomes considerably cheaper and the cost advantages are greater at higher application rates of 50 m3 /ha (Cotching et al. 2008). The cost advantage applies to lime amended biosolids due to its ability to increase soil pH but if a pH boost is not needed or is unlikely to produce a yield response, then the cost advantage of lime amended biosolids is negated. Despite the high cost of inorganic NPK fertiliser, there are clear practical and logistical advantages in using it. It can be ordered immediately before use, it requires minimal storage and relatively little equipment to apply. On the other hand, biosolids require specialised storage sites, all weather road access and considerable investment in heavy equipment to spread it (Figure 6). There is also the issue of finding sufficient land away from permanent dwellings or urban areas to apply it.

Figure 6. Specialised equipment used for applying biosolids to land in southern Tasmania.

Biochar

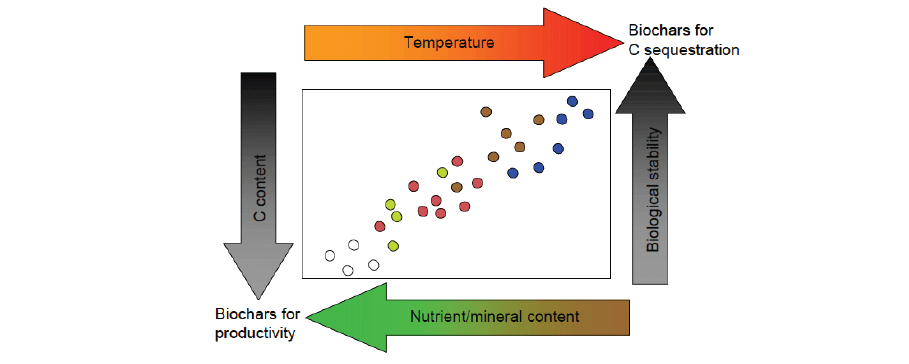

Biochar refers to the carbon-rich material (charcoal) produced from the slow pyrolysis (heating in the absence of oxygen) of biomass. Biomass feedstocks can include forestry and agricultural waste products (e.g. crop straw, chicken manure, woody weeds) municipal green waste, animal manure, and some industrial wastes such as paper mill wastes. There is considerable interest in using biochar for organic waste management, carbon sequestration in soils and as an amendment to improve soil health and agricultural productivity (Lehmann and Joseph 2009). The application of biochar for soil amendment is largely based on evidence about soil fertility and crop productivity gains made in the Amazonian Black Earth (terra preta) (Sombroek 1966). Biochar is produced by pyrolysis of biomass at temperatures between 300 and 1,000°C under low or no oxygen conditions (Jeffery et al. 2011). All biochars are not the same. Key chemical and physical properties of biochar are greatly affected both by choice of feedstock and the way it is made (temperature, residence time, heating rate and feedstock preparation) (Figure 7). These properties affect how the biochar interacts with the soil, how quickly it breaks down and what benefits it might provide to the soil and plant growth.

Figure 7: Biochars produced from different feedstocks (coloured circles) and at different temperature vary in their properties (Soil quality 2022).

Several studies have been conducted where biochar application has shown significant agronomic benefits. However, these results are not universal as other studies have shown no difference, or even some decline, in productivity (Ives 2013; Hardie et al. 2014). The reason lies in the wide range of properties between different biochars, and variation in impact due to interaction with different soil types. In a Tasmanian study, some porosity parameters improved, some showed no change and bulk density decreased. Differences were attributed to the formation of large macropores (>1,200 μm) resulting from greater earthworm burrowing based on observations of earthworm presence in the biochar amended soil. The increased macroporosity associated with biochar addition resulted in a significantly greater volume of leachate and concentration of phosphorous that resulted in significantly larger amounts of potassium and phosphorous being leached from the biochar treatment. Apple crop yield and fruit quality parameters as well as photosynthetic capacity, leaf nutrient concentration and seasonal daily tree water use were unaffected by the addition of biochar or biochar/compost blends (Eyles et al. 2015). Biochar amendment at 10 T/ha did not improve crop yield or other yield parameters of cauliflower, peas and broccoli crops on red Ferrosols and soil chemical and physical properties were unaffected by either biochar application or the interaction between biochar and fertiliser (Boersma et al. 2017).

Dairy effluent

Dairy effluent is a valuable source of nutrients that typically contains relatively large amounts of readily plant available nutrients, particularly nitrogen (N) and potassium (K). The amount of K in effluent normally sets the minimum area to be used or the maximum application rate. Aim to spread effluent as far as possible across the farm. A minimum of 10% farm area or 1 ha/20 cows milked is an accepted rule of thumb. A lighter rate over a larger area is preferable to overloading a small area. Total potassium per application should be no more than 60 kg K/ha, and no more than 120 kg K/ha per year (Brown 2015). The total nitrogen application should be no more than 50 kg N/ha per application. Soil K levels in paddocks that have been repeatedly used for effluent disposal often have very high K levels with levels greater than 1000 ppm found in some paddocks close to dairy sheds in Tasmania. These paddocks will not require application of potassium fertiliser (subject to a soil test). The excessive level of soil K in effluent paddocks should be lowered by cutting hay or silage to remove the excess potassium and feeding this out on other areas of the farm. Avoid applying effluent to paddocks used to calve down the herd as the excess potassium can lead to grass tetany when blood magnesium levels fall below a critical level, with cows going down due to induced magnesium deficiency. Also avoid applying effluent to calf paddocks to minimise risk of bovine Johne’s transfer. In most cases, the period of time before application to pasture and the dilution effect of the wash-down water, tend to reduce the disease risk to stock that graze paddocks treated with effluent.

Rotate effluent applications around at least three or four different areas of the farm if possible, to avoid excessive build-up of nutrients in the soil (Figure 8). Conduct regular soil testing of the areas where effluent is being applied to monitor nutrient levels and soil health. Where possible effluent applications should be synchronised with paddock rotations to allow sufficient time between application and grazing. A standard practice is for at least a 21-day interval to allow time to overcome any palatability or fouling issues and reduce the risk of excess nitrate levels. In summer, 2 weeks is the recommended minimum before grazing. In winter, 3 weeks is the recommended minimum (Brown 2015).

Best plant growth responses are obtained when effluent is applied to actively growing crops or pastures in the warmer months of the year. This is due largely to responses to the N content and to a lesser extent the water content. This also decreases the risk of losses to the environment if effluent is applied when soils are wet. Forage crops, such as turnips or rape, have been found to give excellent responses to effluent. Empty storage ponds prior to winter to ensure ponds have adequate holding capacity for effluent generated from the dairy when soils are too wet to irrigate. In Tasmania, ideal times for applying effluent are the end of spring (November & December) and then soon after the autumn break. Quite often, a single irrigation onto a fodder crop at this time of the year will significantly improve yields.

Dairy sludge extracted from the bottom of treatment ponds is physically and chemically quite different to the liquid effluent. Its high solids content, typically 6-8% dry matter as spread, is usually spread by a slurry tanker which influences when and how it can be used. Applied sludge acts as a long-acting, slow-release fertiliser as most of the nutrients are in organic forms that need to be mineralised to convert them to plant available forms. Sludge is typically higher in phosphorus (P) than effluent and can be applied to paddocks that require capital P fertiliser. Make sure you get a soil test prior to spreading of sludge to ensure excess nutrients are not applied. Sludge can be applied directly to established pasture or to cultivated ground and incorporated into the soil prior to sowing of a crop. The time between application and grazing may be up to 6 – 8 weeks due to the solids content. Apply sludge in the drier months, to enable the water content to drain and evaporate off leaving the nutrient rich solids on the soil surface. Application rates are usually limited by trafficability over the spread area and typically are not more than 5 – 10 mm (50,000 – 100,000 L/ha). Apply effluent or sludge on areas well away from watercourses or drainage lines as any effluent or sludge applied to land should not leave the farm boundary or pollute any surface waterway or ground water.

How to work out how much nutrient you are applying in irrigated effluent (Brown 2015):

- Collect an effluent sample for analysis. This must be as applied to the paddock via the irrigator. It is pointless to take a sample from the top of the pond. A good way is to put out buckets while the irrigator is going. Measure the amount that the irrigator is applying (mm), remembering that 100 mm/ha is equivalent to 1 ML per ha.

- Keep the effluent sample cold and get it to a laboratory for analysis ASAP.

- Look at the analysis for nutrients in ppm and convert to kg nutrient per ML.

For example:

- ammonium 8.58 ppm = 8.58 kg in 1ML

- phosphorus 18.71 ppm = 18.71 kg in 1 ML

- potassium 58.43ppm = 58.43 kg in 1ML

4. Convert kg per ML to total annual application based on total effluent irrigation for the year.

For example:

- Effluent irrigator applies 4 mm/ha each application, with 30 applications per year to the same paddock. 4 mm x 30 = 120 mm/ha/year = 1.2 ML/ha per year.

- Effluent analysis shows potassium (K) at 58.43 ppm = 58.43 kg in 1 ML, which is 70.11 kg in 1.2 ML.

Therefore, the effluent paddock is receiving 70.11 kg K/ha per year.

Figure 8. Rotate effluent applications around at least three or four different areas of the farm Photo by Barry Easton